usp class vi compliant

Class VI testing is aimed to certify that there are no harmful reactions or long-term bodily effects caused by chemicals that leach out of plastic materials. Sil 714001 USP class VI Silicone 1 70 Yes transl.

Sil 714002 USP class VI Silicone 1 70 Yes transl.

. What is ADI-Free BSE-Free TSE-Free. Pharmacopoeia USP Class VI outlines requirements for system toxicity and intracutaneous toxicity for these cleaner compounds. Dursan can be applied to more durable base materials like stainless steel to.

RoHS a European Union Directive restricts the use of certain substances but manufacturers also need to know whether all the ingredients in a medical silicone are made of compliant materials. Moulded O-rings class 1 less than 10 furnace black These can be produced in all possible dimensions up to diameter 1400 mm internal. Enflo products are USP Class VI FDA ROHS REACH and Conflict Materials compliant.

The USP Class VI compounds must be made from ingredients with clear histories of biocompatibility that meet tighter requirements for leachates. Typical applications for our FDA NSF 51 USDA materials are disposable medical. Has a full range of specialty adhesives epoxies primers for polyolefins UV curables and silicones that have been fully tested to meet USP Class VI requirements.

When production of the elastomer contain no ADI with respect to source manufacture and treatment they cannot. USP Class VI testing is conducted by producing an extract of the product with different extraction fluids such as polyethylene glycol and vegetable oil and injecting it in specimen rabbits and mice in vivo alive to observe the biological response to the extract. ISO 90012015 Certified QMS.

The United States Pharmacopoeia USP 30 NF 25 2007 standard also known as Class VI is widely used to comply with stringent FDA regulations for products that come in contact with the human body. The USP outlines classes for plastic materials ie. I - VI with USP Class VI being the strictest requiring that the material exhibit very low levels of toxicity proven.

AFT Fluorotec can manufacture a wide range of components using our USP Class VI PTFE compliant material and are supplying customers worldwide to meet their requirements. The result is a non-toxic bio-inert surface that is USP Class VI compliant that wont contaminate or otherwise harm processes or people. Suitability under USP Class VI is typically a base requirement for medical device manufacturers.

Pharmacopoeia Class VI judges the suitability of plastic material intended for use as containers or accessories for parenteral preparations. Overview of USP Class VI Approved Plastic Materials. Some medical silicones must meet USP Class VI FDA CFR 21 1772600 and RoHS requirements.

USP Class Testing standards are determined by the United States. Table 1 shows our standard programme FDA compliant com- FDA and USP class VI compliant. One of the first guides to biocompatibility was published by the United States Pharmacopeia in 1990 was USP which includes the criteria for USP Class VI Testing.

In an effort to standardize biocompatibility testing worldwide the International Standards Organization ISO developed ISO 10993. Coatings like Dursan prevent system cross contamination while improving corrosion resistance and durability. USP Class VI Approved Plastic Materials.

Professional Plastics General Product. Consumers implicitly rely upon the standards put into place by governing agencies to protect the publics health and well-being. Master Bond systems are very versatile and can be used for both disposable and reusable medical devices.

USP Class testing is one of the most common methods of testing to determine bio-compatibility of materials. Compliance to USP Class VI is often requested by users in the biopharmaceutical and medical industries. All these special grade products have passed this rigorous test.

USP Class VI Testing Methods. Sterile and diaphragm valves have USP Class VI PTFE material in them and sanitary pumps require Class VI O-Rings and sealing material. ENFLON is a registered trademark for.

One standard often overlooked but usually published alongside USP Class VI is FDA 21 CFR 1772600. ADI-free certifies that the raw materials used in production of the elastomer contain no Animal Derived Ingredients ADI. Testing is commonly done as per USP.

When evaluating a new product many of our customers immediately jump to USP Class VI approval tests. There are six classes VI being the most rigorous.

Usp Class Vi What Is It And How Does It Apply To Elastomers Barnwell

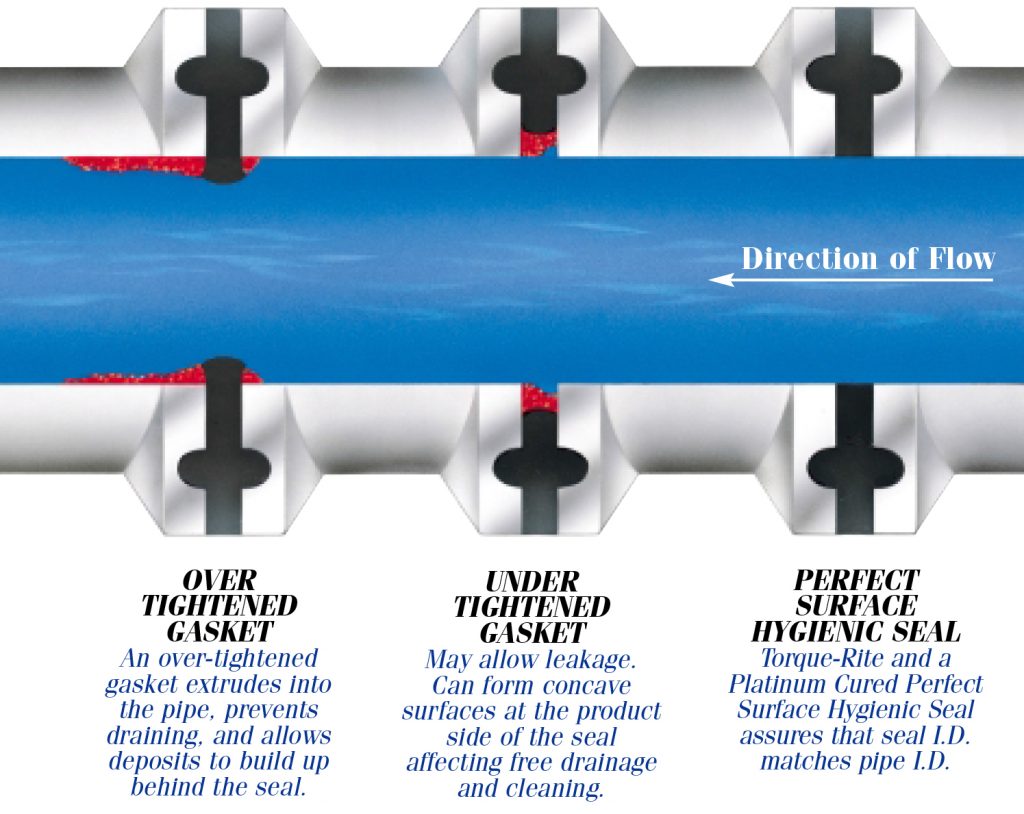

Standard Fda And Usp Class Vi Compliant Materials For All Types Of Hygienic Connections Repassa

Iso 10993 Vs Usp Class Vi Medical Molding And Bicompatible Rubber The Rubber Group

Cls 1480 20 Caps Solid Clear Gl 45 Threads Pfa 6515 Tz Lip Seals Usp Class Vi Chemglass Life Sciences

Double Bagged Usp Class Vi Micro Spatula

Usp Class Vi What Is It And How Does It Apply To Elastomers Barnwell

Double Bagged Usp Class Vi Micro Spatula

Dursan Passes Usp Class Vi Testing Why Is That Important

Double Bagged Usp Class Vi Micro Spatula

Fda Usda Nsf51 Usp Class Vi Compliant Seals Products

Is Dursan Usp Class Vi Compliant

Double Bagged Usp Class Vi Pharmascoop

Why You Need Certified Usp Class Vi Silicones Specialty Silicone Products Inc

1 25 1 1 4 Id Fda Usp Class Vi Platinum Silicone W Polyester Braid Food And Pharma Grade Flex Technologies Incorporated